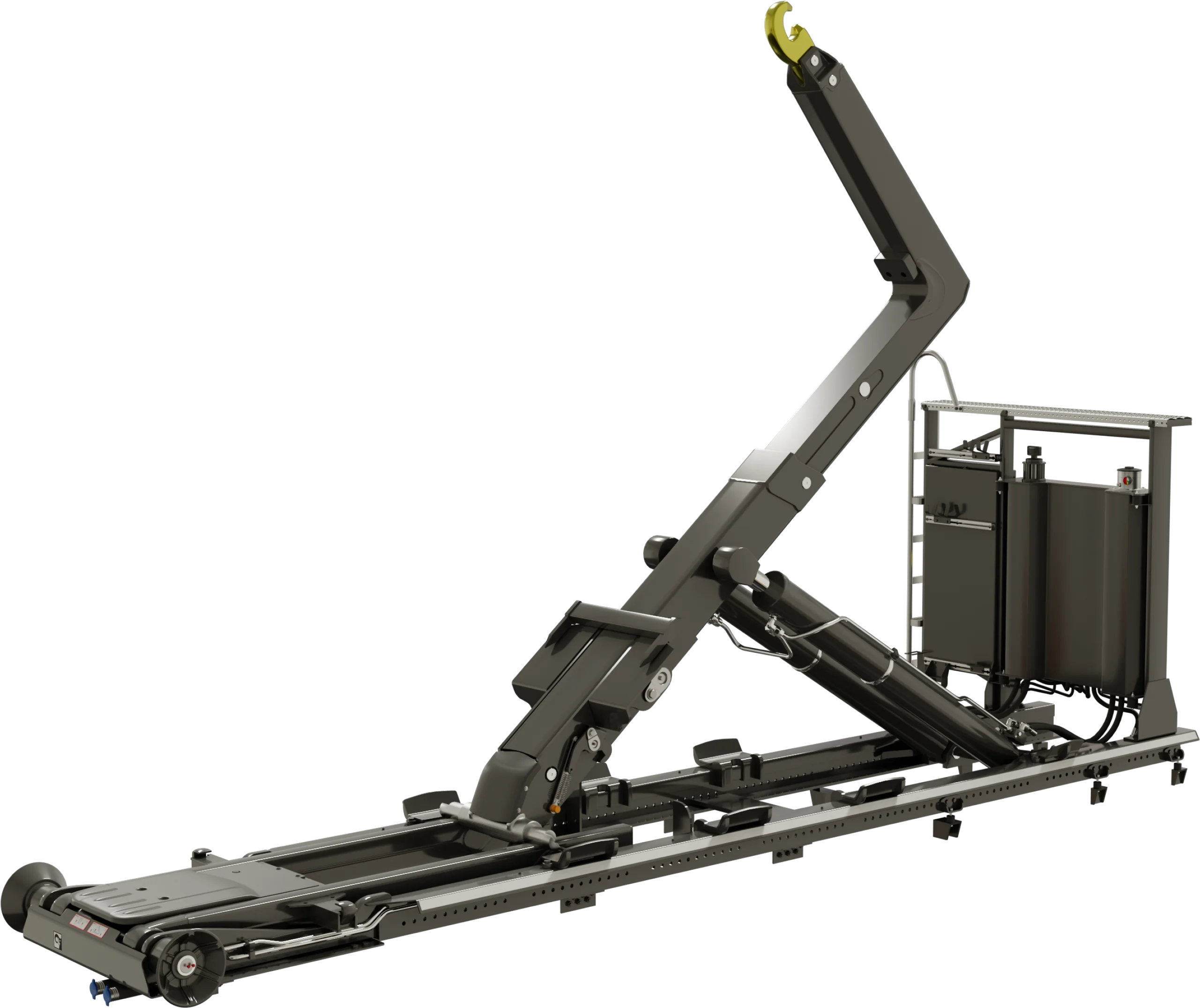

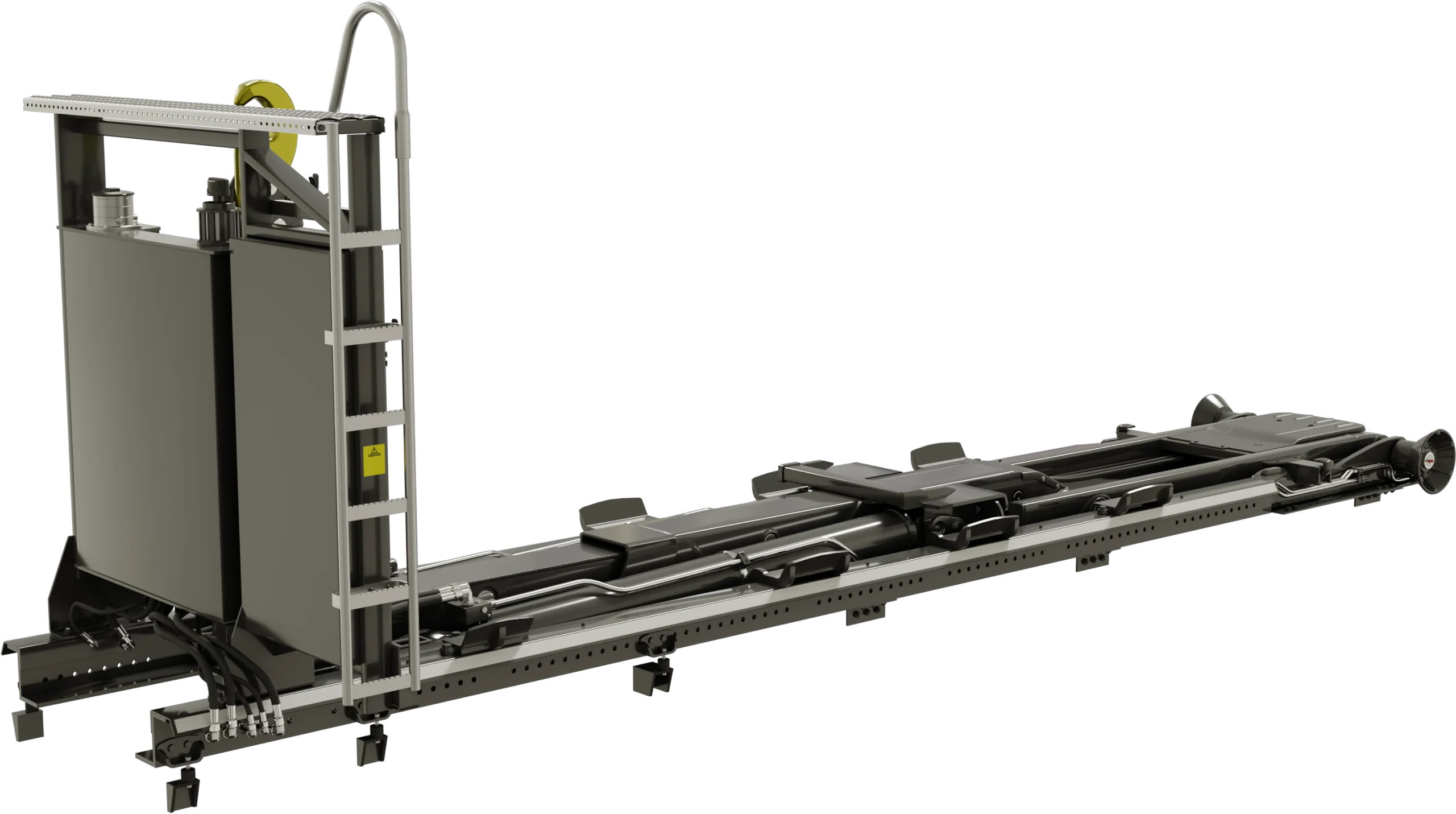

A hook-lifting device installed on the chassis of vans and lorries to handle categorised hook-lift containers of different standards. The main characteristics of a given model depend on the height and length of the vehicle frame, as well as its permissible total weight.

HOOK LIFT

A particular design focus of our equipment is the fulfilment of stringent safety requirements during transport and a reliable hydraulic system adapted to work in difficult conditions. Each type of construction is standardly equipped with a hydraulic container lock and systems protecting against undesirable falling of the lifted load.

| MODEL | NOMINAL LOAD CAPACITY [t] | GVW [t] | HOOK HEIGHT [mm] | CONTAINER LENGTH [mm] | DEVICE LENGTH [mm] | WEIGHT [kg] | WORKING PRESSURE [bar] | COMPATIBILITY WITH THE STANDARD |

|---|---|---|---|---|---|---|---|---|

| ALU-290 | 2 | 3,5 | 900-920 | 2500-3500 | 2500-3000 | 380-430 | 180 | DIN 30722-3 NF R17-108 classe 1 |

| ALU-690 | 69 | 6,0-9,0 | 900-920 | 3000-4000 | 3000-3500 | 430-650 | 280 | DIN 30722-3 NF R17-108 classe 1 |

| ALU-890 | 8 | 12 | 900-920 | 3500-5000 | 3000-4000 | 670-850 | 280 | DIN 30722-3 NF R17-108 classe 1 |

| ALU-2414 | 24 | 26-32 | 1425 | 4500-7000 | 6000 | 2200 | 350 | NF R17-108 classe 2 |

| ALU-3014 | 30 | 26-32 | 1425 | 5000-7500 | 6250 | 2300 | 350 | NF R17-108 classe 2 |

| ALU-2415 | 24 | 26-32 | 1570 | 4500-7000 | 6000 | 2300 | 350 | DIN 30722-1 |

| ALU-3015 | 30 | 23-32 | 1570 | 5000-7500 | 6250 | 2400 | 350 | DIN 30722-2 |

STANDARD EQUIPMENT

- hydraulic container lock

- lifting hook latch

- hydraulic lifting cylinder lock

- remote control

- wheel arches

- overrun protection

- full documentation

OPTIONAL EQUIPMENT

- rear support beam with roller

- light bar

- toolbox

VEHICLE PREPARATION

- adaptation of the vehicle frame to the selected bodywork

- installation of hydraulic attachment in (if it is not present)

- body colour change (possibly maintenance work)

- additional vehicle lighting

The high-quality hydraulic components used have individually assigned serial numbers for fast and efficient service throughout the EU. Thanks to an extensive network of mobile technicians, the replacement or repair of a faulty component can be carried out in the shortest possible time.